kWeld – fuse

2017-07-15

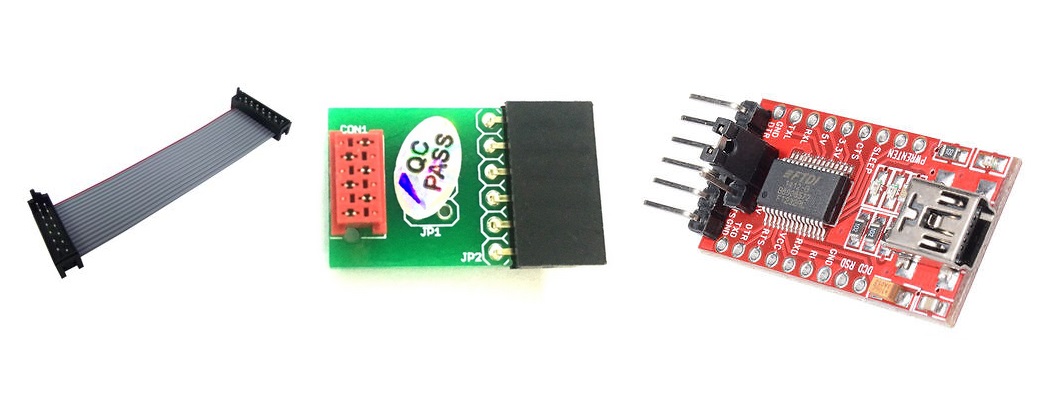

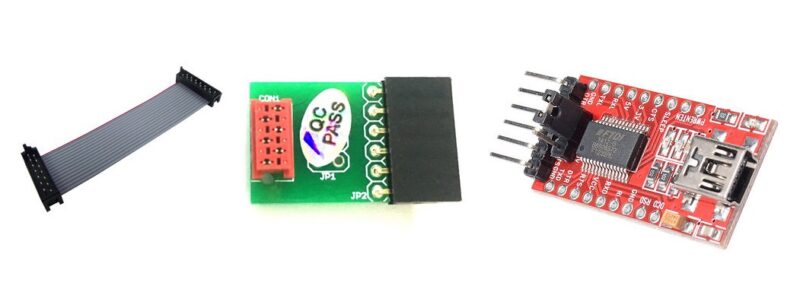

kWeld – firmware update tool

2017-08-07To customers from the U.S., Canada or Mexico: visit our North America reseller here

To Australian customers: visit our local reseller here

To customers in the Czech Republic: visit our local reseller here

New design featuring C14500 (tellurium copper) CNC’ed electrode system for better heat handling capacity and improved handling:

The assembly and operating manuals are available on this website for download (https://www.keenlab.de/wp-content/uploads/2018/07/kWeld-assembly-manual-r5.0.pdf – https://www.keenlab.de/wp-content/uploads/2018/07/kWeld-operation-manual-r3.0.pdf). Please make sure to study them carefully in order to ensure safe and reliable operation.

Checkout this independent review and comparison: https://cellsaviors.com/blog/best-spot-welders

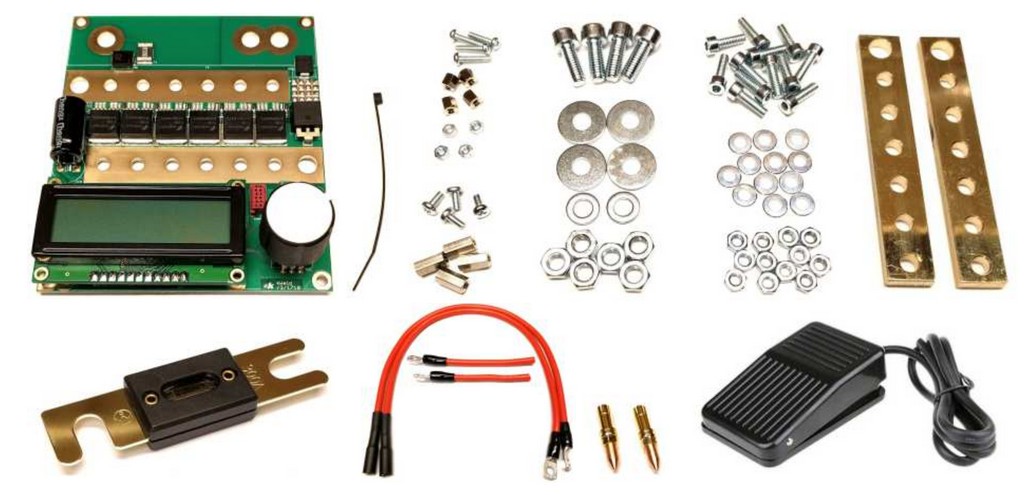

Purchase this item if you want to receive everything that is needed to build a kWeld unit. Complete the kit using basic tools, add a suitable power source, and start welding.

If you want to source some parts from e.g. your local hardware store, then this article may not give you the necessary flexibility and options; in this case, you can order the individual components from the shop instead, and use the description below for an overview of what is needed to build a complete kit.

The kit includes:

| Electronics | This is the brain of the kWeld battery spot welder. You purchase a professionally reflow soldered, tested and programmed electronic module. See https://www.keenlab.de/index.php/product/kweld-electronics/ for more details. |

| Cables, electrode holders, and electrodes | All bits and pieces that are required to fully assemble the kWeld cabling, including a pair of electrode holders and a pair of electrodes. (See https://www.keenlab.de/index.php/product/kweld-cable-electrode-holders/ and https://www.keenlab.de/index.php/product/kweld-electrode-set/ for details.) The power input connection consists of loose cable ends, you need to add a connector that matches your power source. Suitable XT150 power connectors are available in the shop.

Choose the supplied loose option if you have the time and tools do do the necessary assembly steps yourself, saving some money. Check out the assembly manual for an overview of the involved work. If you are in doubt, choose the assembled option here. |

| Fuse | A 300A high current fuse (type ANL) that needs to be mounted on the kWeld electronic module and protects the system from the consequences of unlikely catastrophic failures. |

| Foot switch | The pulse trigger switch of the kWeld system. It has a rugged construction, and uses a real micro switch that is also easy to service. The cable length is 2.0m. |

| CNC machined bus bars | These need to be bolted to the electronics module and provide a low impedance path between the switch transistors and the cable system. |

| Mechanical parts | All bits and pieces that are required to fully assemble the kWeld electronics module with the LCD, the cabling, the fuse, and the bus bars. See https://www.keenlab.de/index.php/product/kweld-mechanical-parts/ for more details. |

Please note that a power supply is not part of the kit. The following high current power supplies have been tested with the kWeld system and can be recommended:

- Turnigy nano-tech 3S/5000mAh/130C Lithium Polymer battery (link). I have stress tested one of them for several complete discharge cycles, and it shows no visible swell thereafter. The measured current is 1300-1500 amperes.

- Turnigy graphene 3S/6000mAh/65C Lithium Polymer battery (link). These do not show any swell after a few full power discharge cycles, but I have no data on their life span yet. The current level is comparable with the nano-tech model.

- Turnigy Nano-Tech Plus 3S/5000mAh/70C Lithium Polymer battery (link), calibrates at around 1500 amps (fully charged).

- Turnigy Graphene Panther 3S/5000mAh/75C Lithium Polymer battery (link), calibrates at around 1600 amps (fully charged).

- Ultracell UXL65-12 (link). According to feedback from a user, the current reported by kWeld is approx 1000A when tested with 0.15mm nickel strips.

- Bosch SMT 31-100. According to feedback from a user, the welding current reported by kWeld is approx 1400A.

- Varta model 577 400 078 (link). According to feedback from a user, the welding current reported by kWeld is 1400 to 1600A.

- Varta model 574 012 068 (link). According to feedback from a user, the calibration current reported by kWeld is 1600A.

- Varta model 560 901 068 (link). According to feedback from a user, the calibration current reported by kWeld is 1700A.

- The power supply must be able to deliver at least 800A (recommended: at least 1000A) to ensure proper functionality of the device.

IMPORTANT: Lithium Polymer batteries are potentially dangerous. If they fail internally, they can spontaneously self-ignite. It is therefore strongly advised to permanently supervise them during use and also while charging them, and to store them in a fire safe container when not using them.

WARNING:

You are dealing with very high energy levels when using this system, which may result in personal injury or fire when handled improperly. Take appropriate safety measures and use this system with caution. Never leave it unattended while being powered.

This product contains small parts, keep out of reach of children!

This system produces significant magnet fields, do not use it when you have a cardiac pacemaker!

Disclaimer:

This kit is provided as is without any guarantees or warranty, except where obliged by national law. In association with the product, www.keenlab.de makes no warranties of any kind, either express or implied, including but not limited to warranties of merchantability, fitness for a particular purpose, of title, or of noninfringement of third party rights. Use of the kit by a user is at the user’s risk.

In no event shall www.keenlab.de be liable for any direct, indirect, punitive, incidental, special, or consequential damages whatsoever arising out of or connected with the use or misuse of any product purchased herein. You agree and acknowledge that any product purchased should be used at your own risk and you should assess the risks before purchasing any product or using any product. You agree that in the event that www.keenlab.de is deemed liable for any harm caused, the amount which it shall be liable to you shall be limited to the cost of the product.

NO REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED, OF MERCHANTABILITY, FITNESS FOR A SPECIFIC PURPOSE, THE PRODUCTS TO WHICH THE INFORMATION MENTIONS MAY BE USED WITHOUT INFRINGING THE INTELLECTUAL PROPERTY RIGHTS OF OTHERS, OR OF ANY OTHER NATURE ARE MADE WITH RESPECT TO INFORMATION OR THE PRODUCT TO WHICH INFORMATION MENTIONS. IN NO CASE SHALL THE INFORMATION BE CONSIDERED A PART OF OUR TERMS AND CONDITIONS OF SALE.

| Weight | 0,8 kg |

|---|---|

| Dimensions | 20 × 20 × 15 cm |

| cables | cables supplied loose, cables assembled |

11 reviews for kWeld – complete kit

You must be logged in to post a review.

jimmyhammar1 (verified owner) –

Really a total newb here so cannot get technical, but that also part of why this little beauty is so great, someone like me can just get one and start putting together battery packs. A China welder based on a transformer is not really that much cheaper if going low end China welders but with this one there is no worries and learning period, perfect result each time.

Highly recommend, ohh also the seller is also perfect and fast with all mail contact so far, could not be happier and money well spent.

Werner Hopf (verified owner) –

Als Besitzer eines Akkupunktschweißers vom chinesischen Quasimonopolisten für Hobbyisten war ich mit dessen Gerät im Gegensatz zu anderen gar nicht so unzufrieden. Die gebauten Akkupacks erfüllten meine Erwartungen. Es gab jedoch Einschränkungen:

1. Mit 0.2mm Nickelband war das Gerät am Anschlag

2. Bei voluminöseren Akkupacks, deren Form vorgegeben war (z. B. Erneuerung Werkzeugakku, Notebookakku) erwies sich die Elektrodenbefestigung als 5 cm vom Gerät entfernter “Haken” als hinderlich. Manchmal wären trotz Fußpedal 3 oder 4 Hände zum Halten nötig gewesen.

3. Der FI meiner Hausinstallation verträgt den induktiven Einschaltimplus des 220V-Geräts nicht und löst aus, lange bevor man überhaupt ans Schweißen denken kann. Zum Glück wohne ich in einem Mehrgenerationenhaus, dessen erste Installation noch aus der Vor-FI-Zeit stammt. Also keine Sorge. Ich habe nichts überbrückt und betreibe bzw. betrieb den Punktschweißer zusätzlich an einer aufgesetzten Sicherheitssteckdose. Doch insgesamt deckt sich das mit den Erfahrungen von Makern aus den USA. Mit deren 110V-Netz geht mit diesen Punktschweißgeräten auf Transformatorbasis fast gar nichts mehr. Und für mich war das Hin- und Hergespringe lästig.

Trotzdem wollte ich erst für den Punktschweißer eine flexible Elektrode vergleichbar mit der des kWeld erwerben. Doch das wäre für mein Modell eine Bastellösung geworden, da nicht vorgesehen (wenn auch im Inet angeboten mit “Bauanleitung”). Bei der Recherche stieß ich auf den kWeld und ließ mich überzeugen mehr Geld in die Hand zu nehmen. Vor allem die Aussicht den kWeld mit ohnehin vorhandenen Akkupacks betreiben zu können gab letztlich den Ausschlag.

Das Kit musste wegen fehlenden Bestands vorbestellt werden. Von da an gab es dann allerdings nur noch positive Überraschungen:

– Der angegebene “WiederAufLagerTermin” wurde eingehalten.

– Die Abwicklung ging schnell (6.7.19 bestellt, ab 9.7.19 wieder auf Lager, Ankunft 12.7.19) und professionell.

– Der Zusammenbau ist mit vorbildlicher Anleitung kein Problem.

– An meine mittlerweile etwas betagte “24V- Ladestation” bestehend aus 8x A123 LiFePO4 (AMP20M1HD-A) 20Ah mit EC5-Stecker angeschlossen, kWeld kalibriert, und die Probeschweißungen mit 0,1 – 0,3mm (Rein-)Nickelband waren unglaublich gleichmäßig und bombenfest.

– Einstell- und vor allem Analysemöglichkeiten von denen ich bisher nur träumen konnte. Trotzdem intuitiv bedienbar.

– Erster “wirklicher” Akkupack (Rasenmäherakku) funktioniert einwandfrei und wäre schon mechanisch mit dem alten Punktschweißer kaum relasierbar gewesen.

Fazit: Ich kann das Gerät jedem der in diese Richtung Ambitionen hat nur wärmstens empfehlen.

razor_sparks (verified owner) –

This thing is so easy to use once set up and calibrated properly. You do need a few tools to get things assembled properly, like a good soldering iron, some metric wrenches, some metric Allen keys, a hex lug crimping tool (and some spare lugs for practice, because you get ONE SHOT with crimping the probes!), some extra heat shrink, and patience. But this thing can WELD! I’m running mine off of a pouch lithium pack meant for RC cars and it actually Overcurrent’d the first time trying to calibrate it, I had to add extra wire to REDUCE the current! (Seriously, this whole system is so overbuilt for performance it’s ridiculous.) [Maryland, USA]

toppngo (verified owner) –

Fast delivery. Kit is very wellt built, proverbial German quality. I use a Lipo 7s, 5 Ah, 80C which delivers approx. 1600A. With this setup I can weld together 4 pieces of 0.15mm pure nickel strips at only 15 Joules.

kyle.longstaff (verified owner) –

Good at first but broke quickly.

I initially bought this at the beginning of the pandemic, and when I received it I was overwhelmed with the quality and ease of use this welder provided. I was finally able to weld proper 0.2mm nickel and copper 🙂

I was building lots of packs and having much success with this welder until one day the foot switch decided to stop working..

I contacted kweld for support and they advised to use Automatic welding function instead…

Then a week or two after, I decided to 3D print the kWeld housing.

(I thought this would be smart since it will cover up the screws and make sure noth bad happens.)

But this was not a good idea.

When I tried plugging in the battery to the welder, it did not turn on. I only saw a little smoke coming from the screw terminal and a burnt smell.

I’m not sure how this could have happened.. When i reassembled it i folowed all instructions.

But overall i managed to get ~10 packs out with this welder so it was almost worth it 🙂 i might buy again since its got good reviews but im not sure…

Frank –

Hi Kyle,

a pity to hear that. But I should be able to help you with replacement parts, just contact me via email frank.boeh(at)keenlab.de (the review system doesn’t allow for a proper conversation). I’d like to explore first why the unit may have failed, in order to prevent this from happening again. The unit shouldn’t fail even after ten thousands of welds.

Cheers Frank

stefan-3702 (verified owner) –

From electronics and software perspective the spotwelder is well designed. Basically it is a high current switch that can time the on-time. Based on the measured voltage and current the on-time is controlled to have constant energy in the weld nudget. For a consistant resistive spotweld the applied electrode force, the current and the weld time are important. One of the major limitations is that the current is determined by the power source and cannot be controlled easily while being key for a good weld. With the current you can control the temperature of the weld which is important when using various alloys. A constant electrode force is important to have constant weld resistance that is important for a constant current if your voltage source is constant. The weld time is important in the hole process of melting and solidification of the nudget. I find the lack of current control the biggest disadvantage.

To give a concrete example when welding something to a nickel plated steel strip the weld current was too low because of the relative high resistance of steel. When I increase the energy it does not help because what happens is that only the weld time increases but the nudget just does not get hot enough. So I can only increase the voltage of the power source.

ptarant (verified owner) –

The product was delivered in good shape, no issues. I assembled the kit as described in the manual with 3D printed PLA enclosure.

I decided to use a LiPol NanoTech 5500mAh battery. It was possible to achieve consistent repeatable welds after some trials and tuning of energy settings. The welding current was reported around 1100A. It was ok to use either pure nickel strips or the nickel plated steel strips with thicknesses from 0.15 to 0.3 mm as those I had available.

I can only recommend the product.

Regards,

Paul

mastabac (verified owner) –

I wish the stock supply cables were 2-3 more cm longer (if I also put it in box, it’s impossible to connect to a car battery at existing length).

I also wished for the possibility to choose an OLED display instead of LCD.

Hell of a job, really good design. Love the new electrodes.

I wanted initially to buy LiPo battery , but it was impossible to find on local stock a proper 3s above 100C, and did not want to risk my money on fakes with kids around.

I preferred to go in a car service and check a few car batteries instead.

I tested a new Varta Blue EFB Dynamic (N60 12V 60A 640A) which had 1680A in short and produced very correct and repetitive welds without any tuning at low energies. Since it was less than 100E (and has longer life and guarantee), I preferred this battery.

So, Frank, keep up the good work ! And thanks !

ND (verified owner) –

In a nutshell: A great kit for the right price! Fast delivery (to Athens, Greece), excellent assembly instructions, and very easy menus for calibrating, adjusting, etc. I 3D-printed a casing and I tested it with my 3-year old car battery (an EXIDE PREMIUM 64Ah-640CCAmps) which, with short AWG8 power cables bolted on, can still produce about 1400 Amps, good enough for spot-welding a copper-nickel sandwich (0.12mm Cu & 0.15mm Ni) for building high power Li-ion packs.

Cheers Frank!

uniplast21 (verified owner) –

Fantastic little device! I’m impressed how a small device can deliver and regulate so much energy.

Pros:

— Very high current delivery eliminates requirement for pulse-welding that you see in some other cheap spot welders.

— Adjustable automatic mode eliminates the need for a foot pedal. Although, this devices does come and can use one.

— Tells you if there was a problem with the weld you just did.

— Nice LCD and turn knob menu system to adjust various settings.

— Low-voltage cutoff to prevent you from damaging a lithium battery, if that’s how you choose to operate the welder.

— Tells you all the details of the weld you just did if you hold down the foot pedal or keep the probes pressed onto the welded part. It’ll

start scrolling through all the details of the weld.

— Comes with beefy 8 AWG cables that can handle huge amounts of current and are also very low resistance.

— Can be used with either a battery or a power supply. As long as the power supply can handle the amount of current this welder uses.

— This company also has free stl files you can download and print on a 3D printer. These stl files are optional welder and probe enclosures

that help protect the device.

— Crazy quick shipping. It only took 2 days to ship it to my house in the US, and this company is in Germany.

Cons:

— Device doesn’t come with a case by default. You need to 3D print the case from the stl files provided on this site. It would be nice if a

case was included by default in case somebody wants one, but doesn’t have access to a 3D printer. You can buy a laser-cut housing kit

made out of acrylic from this site, though.

— Device will not allow more than 2000A of current to conduct through it. This was a little annoying for me because when I got

the device, I didn’t have a battery to use, but I had a supercapacitor bank. I used the capacitor bank to operate it, but the first thing the

welder does is force you to calibrate the device. This isn’t a bad thing, but if you do what I did, then the supercapacitor bank will provide

more than 2000A of current, which the welder doesn’t like. I was not able to successfully calibrate the device until I got a lithium-ion

battery to operate it. I also can’t use the supercap bank to do any welds because, again, it provides more than 2000A of current. This

company does sell a capacitor bank that will work just fine with the welder, though.

— The probes could be a bit longer. As you use the welder, the probes slowly get duller and worn down, requiring you to take them to a

bench grinder to sharpen them again. The probes are kinda short, so I don’t think I’ll be able to get more than a couple of sharpens out

of them before the set screws won’t be able to grab them anymore.

— Lastly, I wish this welder came with some XT150 connectors. A lot of lithium-ion batteries will either have XT60, XT90, or XT150

connectors on them, and by not including them, the customer is forced to buy some and wait a couple days before being able to use the

welder if they didn’t know that the welder wouldn’t come with those connectors.